In the competitive landscape of juice production, maintaining efficiency and quality is paramount. One of the most significant advancements in this regard is the integration of automated bottling lines. These systems streamline the bottling process, ensuring that beverages are filled, sealed, and labeled with minimal human intervention. This article will explore the purpose and importance of automated bottling lines, highlight their key features and benefits, and discuss cost considerations and investment insights for businesses looking to enhance their production capabilities.

Overview of Automated Bottling Lines

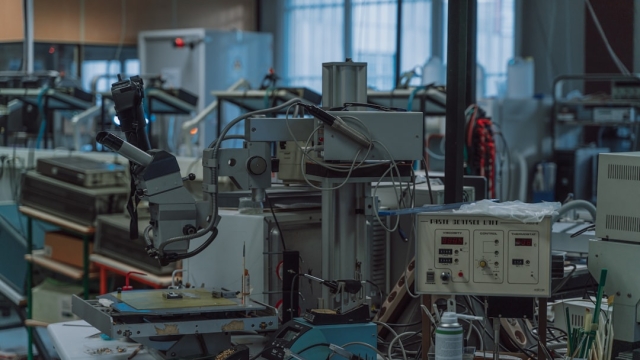

Automated bottling lines are sophisticated systems designed to handle the complete bottling process for beverages, including juices. These lines typically encompass various stages such as washing, filling, capping, and labeling. The primary purpose of these systems is to increase production speed while maintaining high standards of hygiene and quality. By automating these processes, manufacturers can significantly reduce the likelihood of human error, enhance the consistency of their product, and ultimately improve their bottom line.

The importance of automated bottling lines in the juice industry cannot be overstated. As consumer demand for fresh, high-quality juices continues to grow, producers are under pressure to deliver products that meet these expectations efficiently. Automated systems help ensure that the bottling process is swift, accurate, and compliant with industry standards, enabling companies to remain competitive in a rapidly evolving market.

Key Features and Benefits for Juice Production

Automated bottling lines come equipped with numerous features that enhance their functionality and efficiency. Some of the key features include:

- High Speed and Efficiency: Automated systems can operate at high speeds, filling and capping thousands of bottles per hour. This level of efficiency is crucial for meeting production targets and keeping up with consumer demand.

- Precision Filling: These lines utilize advanced filling technologies that ensure precise filling levels, reducing product waste and maintaining consistency across batches.

- Hygiene and Safety: Automated bottling lines are designed with sanitation in mind. Many systems feature easy-to-clean components and materials that minimize contamination risks, ensuring that the juices produced are safe for consumption.

- Integration with Other Systems: Many automated bottling lines can be integrated with upstream processes like juicing and downstream processes such as packaging, creating a seamless production workflow.

In addition to these features, the benefits of implementing automated bottling lines are significant. They can lead to:

- Reduced Labor Costs: By minimizing the need for manual labor, businesses can lower labor costs and reduce the risk of injuries associated with repetitive tasks.

- Improved Product Quality: Automation helps maintain consistent quality and hygiene standards, enhancing the overall product appeal and customer satisfaction.

- Scalability: Automated systems can be scaled up or down based on production needs, allowing businesses to adapt quickly to changing market demands.

Cost Considerations and Investment Insights

When considering an investment in automated bottling lines, several factors influence costs. The initial investment can vary widely based on the size of the operation, the complexity of the system, and the specific features required. Key cost considerations include:

- System Capacity: Larger systems that can handle higher volumes will typically require a greater upfront investment but can lead to lower operating costs in the long run.

- Customization: Customized solutions tailored to specific production needs may incur additional costs, but they can offer significant advantages in efficiency and output.

- Maintenance and Support: Ongoing maintenance and support are essential for keeping bottling lines operational. It’s important to factor in these costs when budgeting for equipment.

In conclusion, automated bottling lines represent a critical investment for juice producers aiming to enhance their production processes. By understanding the features, benefits, and cost considerations associated with these systems, businesses can make informed decisions that align with their operational goals. For those interested in exploring options for automated bottling lines specific to juice production, resources such as specialized suppliers can provide valuable insights and solutions tailored to individual needs.