In the world of industrial operations, mastering the intricacies of valves and controls is essential for ensuring smooth and efficient processes. Valves serve as the gatekeepers regulating the flow of liquids, gases, and other substances within a system, while controls provide the means to monitor and manage these processes effectively. Valworx, an ISO 9001-certified supplier, stands out as a reliable source of high-quality actuated valves and controls, catering to a diverse range of markets including industrial, institutional, and government sectors. With a commitment to delivering top-notch automated valve assemblies built to exacting standards, tested rigorously, and shipped promptly, Valworx exemplifies efficiency and reliability in the realm of valves and controls.

Types of Valves

https://www.valworx.com/category/butterflyvalve

First, let’s talk about ball valves. They are commonly used in industrial applications due to their reliability and durability. With a rotating ball to control the flow of fluids, these valves are suitable for both on/off and throttling applications.

Next, we have butterfly valves, known for their lightweight design and quick operation. These valves are often used in large piping systems where space is limited. By rotating a disc to control the flow, butterfly valves provide efficient and cost-effective flow control solutions.

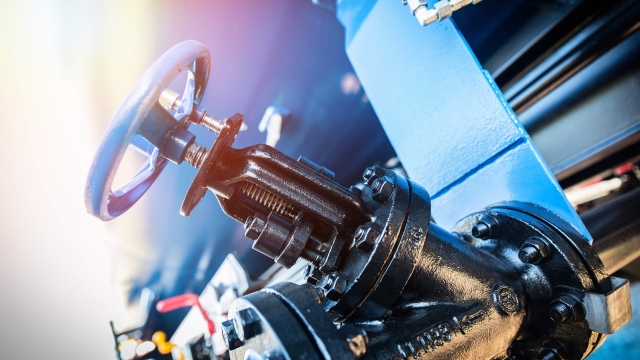

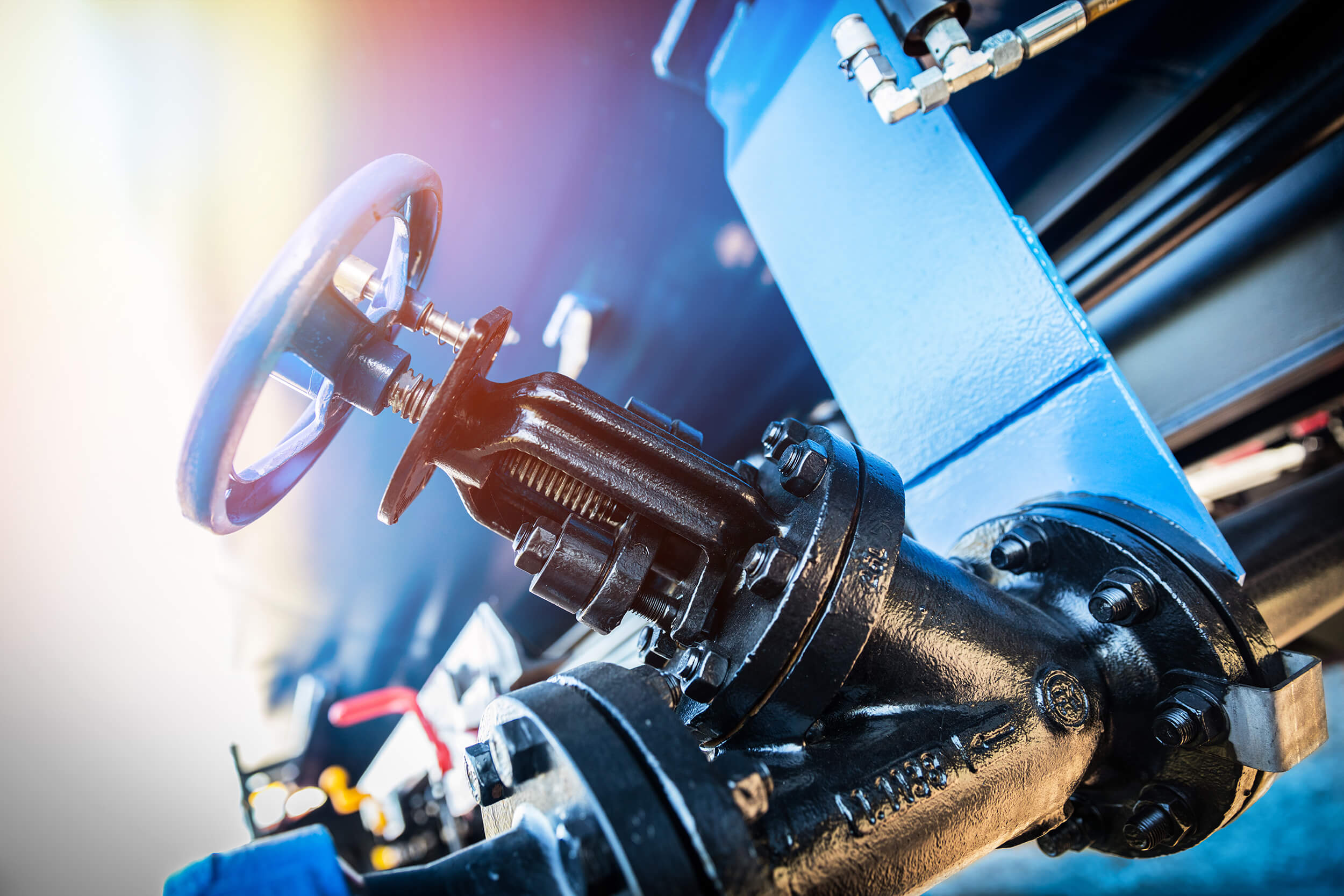

Lastly, gate valves are popular for their tight sealing capabilities. These valves operate by lowering or raising a gate to control the flow of fluids. Gate valves are commonly found in pipelines that require a full flow or complete shut-off.

Importance of Proper Control Systems

Having the right control systems in place is crucial for the optimal functioning of valves in any industrial setup. The ability to regulate flow, pressure, and temperature effectively ensures smooth operations and prevents costly downtime.

Properly designed control systems not only enhance efficiency but also improve safety by providing accurate monitoring and control over the entire valve network. With the right mechanisms in place, operators can quickly respond to changes in conditions and maintain a controlled environment without disruptions.

An automated control system like the ones provided by Valworx streamlines operations by eliminating manual interventions, reducing the risk of human errors, and ensuring consistent performance across all valve assemblies. By investing in reliable control systems, businesses can enhance their productivity and maintain a competitive edge in the market.

Advantages of Automated Valve Assemblies

Automated valve assemblies offer increased efficiency in controlling flow rates and pressure within industrial processes. These assemblies enable precise adjustments to be made remotely, reducing the need for manual intervention and streamlining operations. By integrating automation technologies, such as actuators and sensors, these valve assemblies can be programmed to respond to specific parameters, ensuring optimal performance and consistency.

Another key advantage of automated valve assemblies is their enhanced safety features. By eliminating the need for constant human interaction, these assemblies minimize the risk of accidents and potential hazards in industrial settings. Additionally, automated valves can be equipped with emergency shutdown systems that can swiftly respond to critical situations, preventing damage and ensuring the protection of personnel and equipment.

Furthermore, automated valve assemblies contribute to cost savings through improved resource management. By enhancing control precision and reducing wastage, these assemblies help businesses optimize their operations and maximize productivity. The quick turnaround time offered by suppliers, like Valworx, further supports cost-efficiency by minimizing downtime and ensuring timely delivery of valve solutions to meet varying industrial demands.