In the world of industrial valves, one particular type stands out for its versatility and efficiency: the wedge gate valve. Designed to regulate fluid flow, this valve has revolutionized various industries by providing exceptional control and reliability. Whether it’s handling high-pressure environments or managing substantial volumes of fluids, the wedge gate valve continues to prove its worth time and time again.

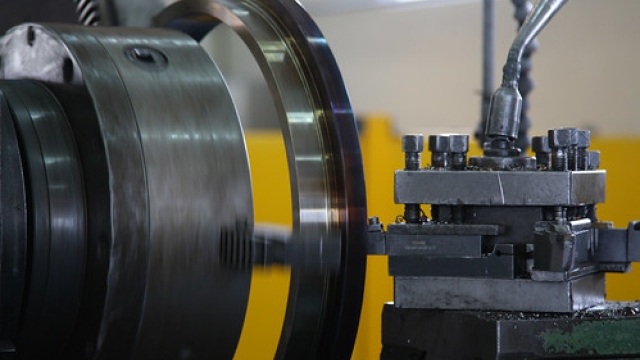

A key feature of the wedge gate valve is its sturdy construction. Typically made from durable materials such as cast iron, this valve can withstand the harshest conditions, ensuring optimal performance and longevity. From controlling water flow in municipal systems to handling intense industrial processes, the wedge gate valve is designed to meet the demands of diverse applications.

One of the standout advantages of the wedge gate valve is its ability to provide a tight and secure seal. Equipped with a solid, wedge-shaped gate, this valve can effectively shut off fluid flow, preventing leaks and minimizing wastage. This makes it an ideal choice for systems that require precise fluid control, such as water gate valves in irrigation networks or flanged gate valves in industrial pipelines.

Stay tuned as we delve deeper into the functionalities and benefits of the wedge gate valve. Whether you’re an engineer, a facility manager, or simply curious about industrial valves, this article will unlock the potential of this efficient fluid control powerhouse. From its design principles to real-world applications, we will explore how the wedge gate valve continues to make a significant impact in the realm of fluid management.

Industrial Valves: Importance and Functionality

Industrial valves are essential components in various fluid control systems. They play a crucial role in regulating the flow, pressure, and direction of fluids within pipelines and other industrial processes. Valves act as gatekeepers, allowing or hindering the passage of liquids, gases, or slurries.

One particular type of valve that has proved to be versatile and efficient in fluid control is the wedge gate valve. Designed with a gate that resembles a wedge shape, this valve is known for its robust performance, reliability, and ease of operation. Its ability to handle a wide range of fluids, pressures, and temperatures makes it a popular choice in industries such as oil and gas, water treatment, and chemical processing.

The wedge gate valve, also referred to as a flanged gate valve, offers exceptional sealing properties. Its gate design allows for a tight and leak-proof closure, minimizing the risk of fluid loss or contamination. This makes it ideal for applications that require a high level of control, such as shut-off and isolation operations.

Another advantage of the wedge gate valve is its ability to handle different types of media, including corrosive and abrasive fluids. With its sturdy construction, often made of cast iron, these valves can withstand challenging environments and remain operational for extended periods without compromising their functionality.

In summary, industrial valves, particularly the wedge gate valve, play a vital role in ensuring the smooth and efficient flow of fluids in various industrial processes. Their ability to regulate, isolate, and control the flow of liquids, gases, or slurries makes them indispensable components in modern fluid control systems.

2. The Versatile Wedge Gate Valve: Features and Applications

The wedge gate valve is one of the most efficient and versatile industrial valves available. It is designed to regulate and control the flow of fluids in various applications. With its unique features and exceptional performance, the wedge gate valve has become a preferred choice in the fluid control industry.

One notable feature of the wedge gate valve is its flanged design, which allows for easy installation and maintenance. This design ensures a tight and secure seal, preventing any leakage or loss of fluid during operation. Whether it is used in water distribution systems, petroleum refineries, or chemical processing plants, the wedge gate valve guarantees reliability and efficiency.

Another advantage of the wedge gate valve is its compatibility with different types of fluids. From water gate valves to cast iron gate valves, this versatile valve can handle a wide range of liquids and gases. This flexibility makes it an ideal choice for various industries where different fluids need to be controlled and regulated accurately.

Furthermore, the wedge gate valve offers excellent resistance to high pressures and temperatures. Its robust construction and durable materials make it suitable for demanding applications that require exceptional performance and reliability. Whether it is operating under extreme temperatures or handling high-pressure fluids, the wedge gate valve ensures smooth and efficient fluid control.

In conclusion, the wedge gate valve stands out as a versatile and efficient solution for fluid control. Its features, including the flanged design, compatibility with different fluids, and resistance to high pressures and temperatures, make it a reliable choice for a wide range of applications. Whether in water systems, industrial plants, or refineries, the wedge gate valve unleashes fluid control with its exceptional performance and versatility.

3. Different Types of Gate Valves and Their Uses

Gate valves are essential components in the world of industrial valves, providing efficient control of fluid flow. Among the various types of gate valves available, the wedge gate valve stands out due to its versatile nature and widespread usage. Let’s explore some of the different types of gate valves and their specific applications.

Wedge Gate Valve:

The wedge gate valve is a popular choice in many industries, primarily due to its exceptional sealing capabilities. Its design features two inclined seats and a wedge-shaped gate between them, allowing for a tight seal when the valve is closed. This type of gate valve is commonly used in applications where a tight shut-off is required, such as oil and gas pipelines, water treatment plants, and power generation facilities.Flanged Gate Valve:

Flanged gate valves are widely used in industries where large pipe sizes are employed. These valves have flanges on both ends, which allow for easy installation and removal. Flanged gate valves are known for their robust construction and ability to handle high-pressure and high-temperature applications. They find extensive use in oil refineries, chemical plants, and petrochemical facilities.

Industrial Valves

Water Gate Valve:

As the name suggests, water gate valves are specifically designed for controlling the flow of water. These valves are commonly used in municipal water supply systems, irrigation networks, and water treatment plants. Water gate valves provide reliable and precise regulation of water flow, ensuring efficient distribution and conservation of this crucial resource.Cast Iron Gate Valve:

Cast iron gate valves are notable for their durability and resistance to corrosion. These valves are often used in applications where the working fluid contains impurities that may cause damage to other types of valves. Cast iron gate valves are commonly found in wastewater treatment plants, sewage systems, and industrial processes involving chemically aggressive environments.

In conclusion, gate valves come in various types, each possessing unique characteristics that make them suitable for specific applications. The wedge gate valve, flanged gate valve, water gate valve, and cast iron gate valve are just a few examples of the diverse range of gate valves available. By understanding their respective uses, industries can make informed decisions when selecting gate valves for their fluid control needs.