In the world of power electronics, one indispensable component stands out – the IGBT module. Offering a crucial link between the high-performance characteristics of insulated gate bipolar transistors (IGBTs) and the robustness of module packaging, IGBT modules play a pivotal role in a wide array of industrial applications. With their ability to handle high power levels while ensuring efficiency and reliability, these modules have become fundamental in modern power systems.

Delving into the realm of IGBT modules, we uncover a wealth of capabilities and opportunities for enhancing power electronics designs. From motor drives and renewable energy systems to industrial automation and beyond, the versatility and performance of IGBT modules have revolutionized the landscape of power conversion technologies. By understanding the intricacies of IGBT module construction, operation, and application, engineers and enthusiasts alike can harness the full potential of these dynamic devices to unleash power in a myriad of innovative ways.

Benefits of IGBT Modules

IGBT modules offer a high level of efficiency in power conversion applications, making them ideal for various industries such as automotive, renewable energy, and industrial automation. These modules allow for smoother switching transitions, reducing power loss and improving overall system performance.

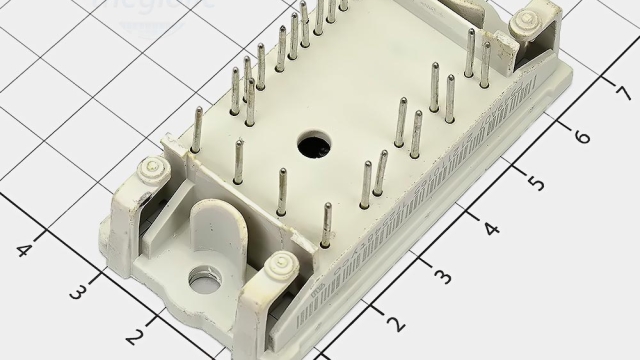

Another key benefit of IGBT modules is their compact size and lightweight design, which enables space-saving installation and ease of handling during assembly. This feature is particularly advantageous in applications where limited space is a concern, as IGBT modules help optimize the use of available space while delivering high power output.

IGBT Module

Furthermore, IGBT modules are known for their reliability and durability, providing long-term operational stability even in harsh environments. This reliability factor ensures uninterrupted performance, reducing maintenance requirements and enhancing the overall lifespan of the power electronics systems they are integrated into.

Applications of IGBT Modules

In the automotive industry, IGBT modules play a vital role in electric vehicle powertrains. They are used in the inverters that control the motor speed, providing efficient and precise power management to drive the vehicle smoothly.

Renewable energy systems such as solar inverters heavily rely on IGBT modules to convert DC power generated by solar panels into usable AC power for homes and businesses. The modules enable efficient energy conversion, ensuring maximum energy harvest from the sun.

Industrial automation benefits from the high switching speed and voltage capabilities of IGBT modules. They are commonly used in variable frequency drives to control the speed and torque of electric motors, optimizing processes in manufacturing plants and machinery.

Best Practices for Using IGBT Modules

When utilizing IGBT modules, it is crucial to ensure proper heat management. Adequate heat sinking and ventilation are key to maintaining optimal performance and extending the lifespan of the modules.

Another important aspect to consider is ensuring appropriate power supply for the IGBT modules. This involves selecting the right voltage and current ratings to match the requirements of the application, thereby maximizing efficiency and reliability.

Regular monitoring and inspection of IGBT modules are essential to detect any potential issues early on. By conducting routine checks, any abnormalities can be identified and addressed promptly to prevent any major malfunctions or failures.