Welcome to the world of IGBT modules, where advanced technology meets efficient power management. IGBT modules play a crucial role in modern electronics and power systems, offering a combination of high switching speed and high energy efficiency. These modules are essential components in various applications, from renewable energy systems to industrial drives, thanks to their ability to handle high power levels while maintaining optimal performance.

Designed to handle high voltages and currents, IGBT modules serve as key building blocks in power electronics circuits, enabling precise control over power flow. Their unique structure, combining the benefits of both MOSFET and BJT transistors, makes them ideal for applications that require the best of both worlds – low on-state voltage drop and high current-carrying capability. With the right knowledge and application, IGBT modules can unleash the full potential of modern power systems, paving the way for enhanced energy efficiency and performance.

Working Principle

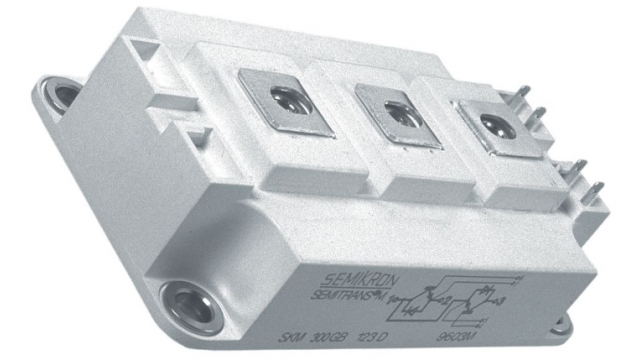

IGBT Modules are semiconductor devices that combine the features of Insulated Gate Bipolar Transistors (IGBTs) and Diodes within a single package. The core function of an IGBT module is to control the flow of electrical current by acting as a switch. This control is crucial in various applications where power regulation and conversion are needed, such as motor drives, inverters, and power supplies.

At the heart of an IGBT module lies the IGBT itself, which is responsible for handling high power levels efficiently. When a voltage is applied to the gate terminal of the IGBT, it triggers the device to conduct electrical current between the collector and emitter terminals. This on/off switching capability allows the IGBT module to regulate the power flow with precision, making it ideal for high-power applications requiring controlled switching operations.

Additionally, IGBT modules are designed with built-in diodes that function to handle reverse current flow and provide protection against voltage spikes. These diodes, known as freewheeling diodes, serve to ensure smooth operation by allowing the current to circulate safely when the IGBT is turned off. By incorporating both IGBTs and diodes into a single module, engineers can simplify the circuit design and enhance the overall efficiency and reliability of power electronics systems.

Advantages

One of the key advantages of IGBT modules is their high efficiency. This efficiency is crucial in various applications, as it helps to reduce energy consumption and heat generation, leading to cost savings and improved performance.

Another benefit of IGBT modules is their ability to handle high voltages and currents with ease. This capability makes them ideal for power electronics applications where robustness and reliability are essential.

Additionally, IGBT modules offer superior switching speed compared to other semiconductor devices. This fast switching capability allows for precise control of power flow, making them suitable for applications requiring high-speed operation.

IGBT Module

Applications

One important application of IGBT modules is in renewable energy systems, where they play a vital role in converting energy from sources such as solar panels or wind turbines into usable electricity. Their ability to handle high voltages and currents makes them ideal for use in inverters and power converters in these systems, contributing to the efficient and reliable generation of green energy.

In the realm of transportation, IGBT modules are widely used in electric vehicles and hybrid electric vehicles to control the flow of power between the battery and the motor. By enabling precise and efficient power management, IGBT modules help enhance the performance and longevity of the vehicle’s powertrain while also contributing to reduced emissions and increased fuel efficiency.

Industrial applications of IGBT modules include motor drives, welding equipment, and uninterruptible power supplies (UPS). In motor drives, IGBT modules are used to vary the speed and torque of electric motors, offering precise control and energy savings. Welding equipment benefits from the high power densities and fast switching speeds of IGBT modules, enabling high-performance welding processes. Additionally, in UPS systems, IGBT modules ensure seamless power backup solutions during power outages to protect critical equipment and maintain operations.